Project Context & Challenge

Military stakeholders across multiple contracts needed to understand what advanced data science could accomplish with existing maintenance datasets. These were primarily proof-of-concept contracts designed to demonstrate AI capabilities and secure follow-on work where deeper user research and full system development would occur.

I worked with Air Force Disposition Engineers, Naval Maintenance Managers, Military Maintenance Technicians, and Program Managers across multiple service branches.

My role was turning technical data science capabilities into practical user experiences. Data scientists delivered technical dashboards, and I translated AI potential into practical UX that showed operational value through rapid prototyping rather than extensive user research.

- Work with unstructured datasets without system integration

- Rapidly prototype data science possibilities rather than conduct extensive user research

- Turn technical AI capabilities into practical user interfaces that show real-world value

- Rapidly learn emerging AI techniques including NLP, normal behavior models, LLMs, and semantic search

The Rapid Prototyping Process

I led each project into rapid prototyping given our primary goal was demonstrating data science possibilities rather than thoroughly addressing all end user needs. We needed to prove AI capabilities through realistic UX implementations that would justify follow-on contracts.

While data scientists delivered Python and Streamlit dashboards showing technical AI capabilities, I conducted enough research to create UX that showed where we could realistically go with these capabilities - turning raw AI potential into practical, usable interfaces.

- Core value was demonstrating AI capabilities through realistic UX that showed real-world applications

- Semantic understanding and advanced NLP could dramatically improve military workflows

- Well-designed AI demonstrations could secure larger contracts for full system development

How We Demonstrated Value

We rapidly demonstrated AI capabilities through realistic UX implementations that showed practical application potential, with success measured by our ability to secure follow-on contracts for full system development.

- Rapid prototyping over extensive user research to gather enough understanding for believable demonstrations

- Realistic UX implementations demonstrating practical application rather than just technical capability

- Focus on "art of the possible" rather than addressing every workflow need

- Work within technical constraints while showing transformation potential

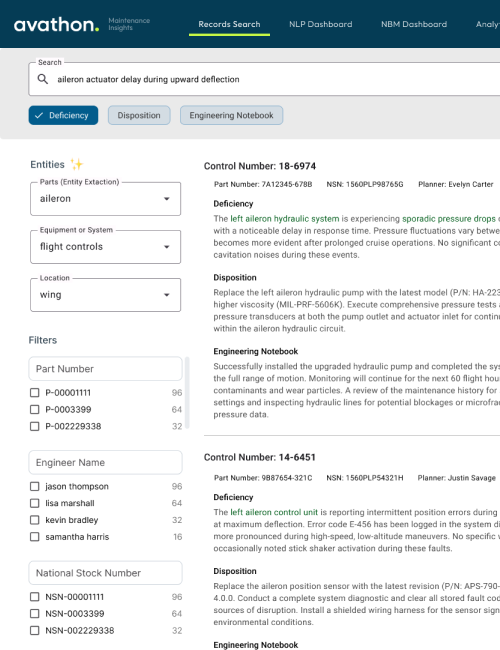

Semantic Search (Air Force)

AI-powered search interface for Air Force Disposition Engineers conducting technical analysis and historical record research.

Natural language processing with semantic understanding, configurable filtering with AI confidence indicators, sub-5-second response times through pre-processed search indexing.

Continuous learning process to understand AI capabilities, then translate into believable user experiences. Progression from basic keyword extraction to advanced semantic search, topic modeling, and LLM integration.

Achieved 6x speed improvement in search response times (30 seconds to under 5 seconds). Implemented production system actively used by Air Force Disposition Engineers with enhanced search accuracy through semantic understanding.

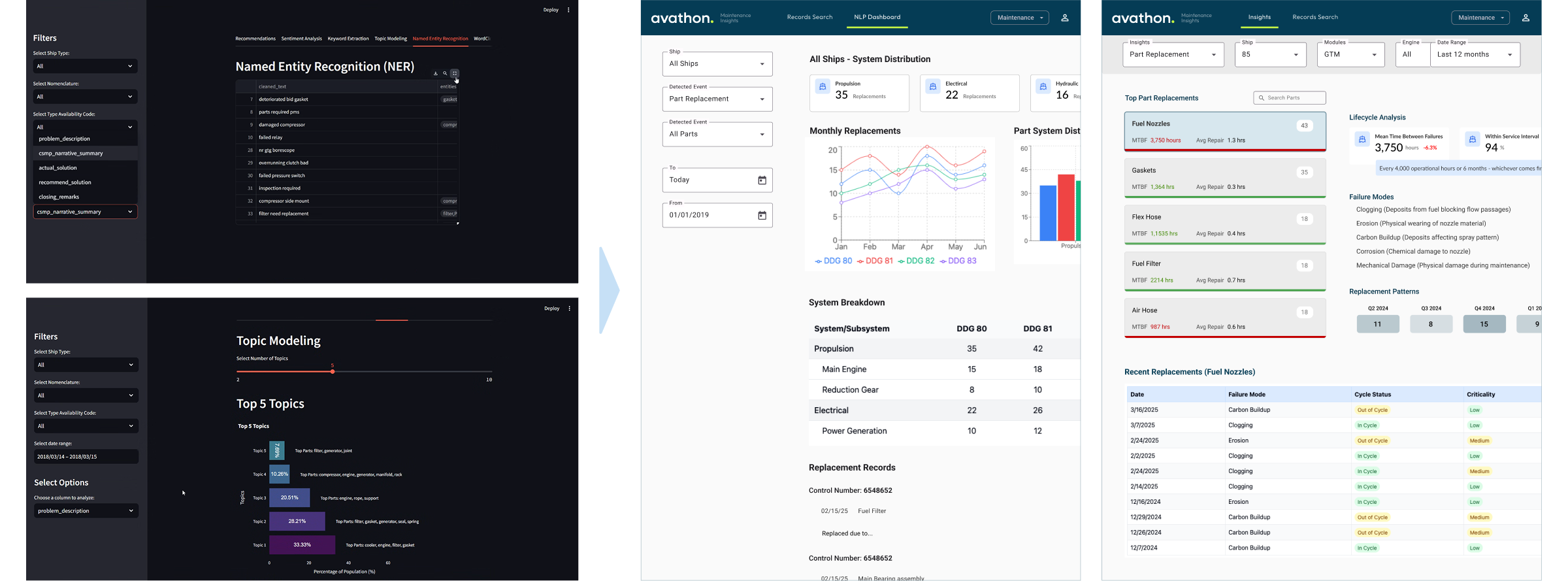

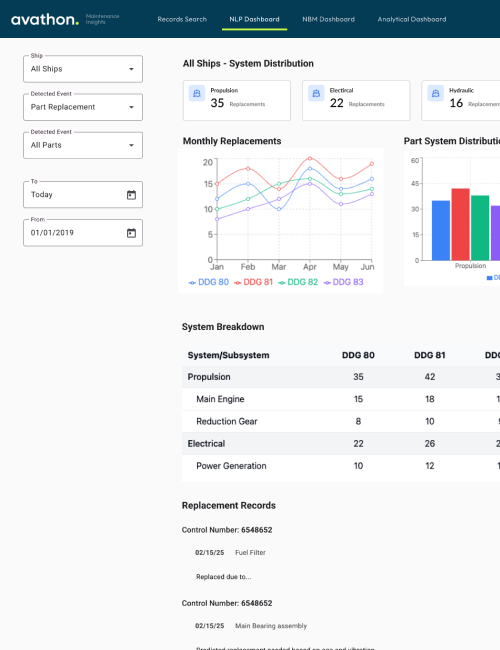

Part Replacement & Breakdown (Navy)

Ship maintenance records analysis and text processing capabilities with automated part failure pattern detection.

Topic modeling for maintenance themes, sentiment analysis of repair reports, named entity recognition for parts and failure modes, automated extraction of replacement patterns from unstructured logs, predictive modeling for component degradation.

Demonstrated advanced NLP capabilities for unstructured maintenance data processing. Automated identification of recurring failure patterns. Enabled data-driven maintenance scheduling and parts inventory optimization.

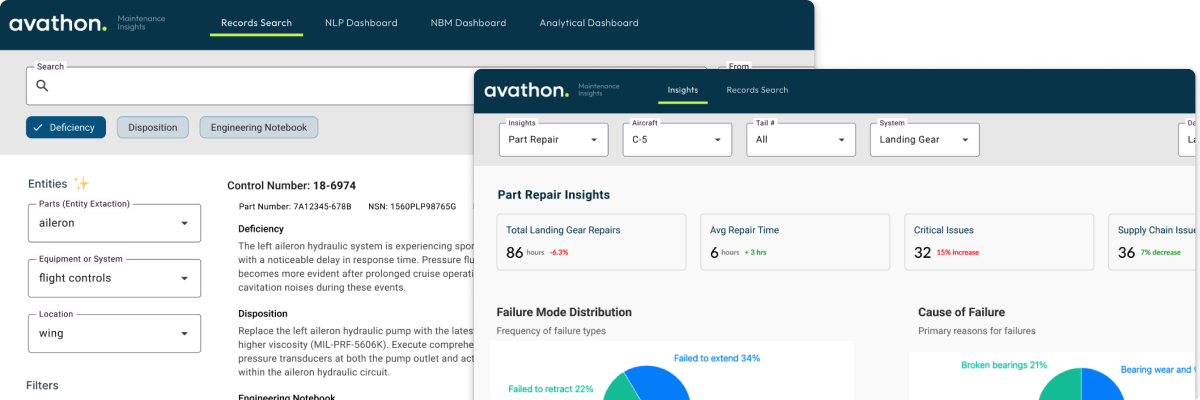

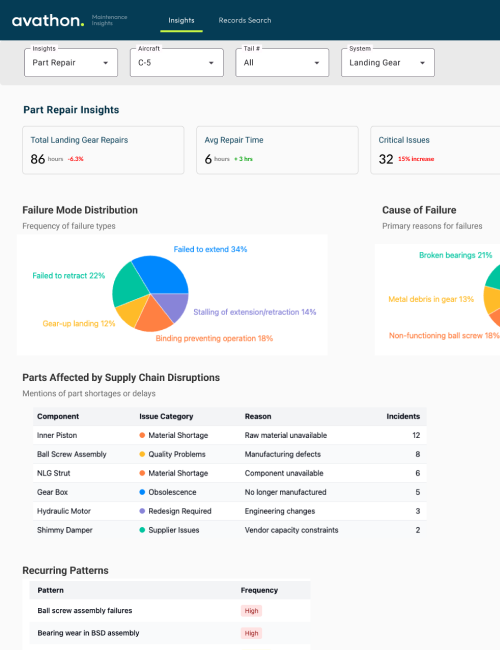

Parts Repair & Lifecycle Analytics (Air Force)

C-5 aircraft component analysis and supply chain intelligence with predictive failure modeling.

Statistical failure mode analysis, parts replacement pattern recognition, NMC (Not Mission Capable) status tracking with root cause analysis, lifecycle management with predictive maintenance windows, supply chain constraint modeling.

Provided complete visibility into aircraft maintenance patterns and supply chain constraints. Identified critical failure modes affecting mission readiness. Enabled proactive parts ordering and maintenance scheduling.

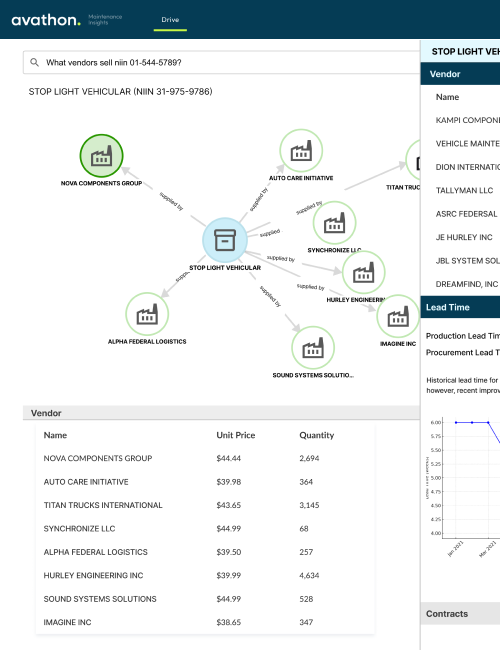

Supply Chain Knowledge Graphs (Multi-service)

Vendor relationships, parts availability, and supply chain risk analysis with LLM-powered natural language querying.

Interactive knowledge graphs with conversational query interface, LLM-to-graph search translation, real-time vendor API integration for live parts availability, scenario modeling with risk propagation analysis, geographical risk assessment.

Enabled data-driven supply chain decisions through relationship visualization. Natural language querying reduced analysis time from hours to minutes. Real-time vendor integration provided up-to-date parts availability across multiple suppliers.

Impact & Key Learnings

- Delivered measurable improvements across multiple military contracts

- Demonstrated AI capabilities informing future technology investments

- Implemented working solutions with detailed prototype demonstrations

- Field research critical in government environments with complex regulatory requirements

- Cross-functional AI collaboration requires bridging user needs and technical capabilities through embedded research

- Constantly learning from data scientists about their techniques. As they move from basic NLP to advanced tools like semantic search and LLMs, it directly shapes how we design the user experience.

- Multi-contract approach enables both immediate operational improvements and technology proof-of-concept